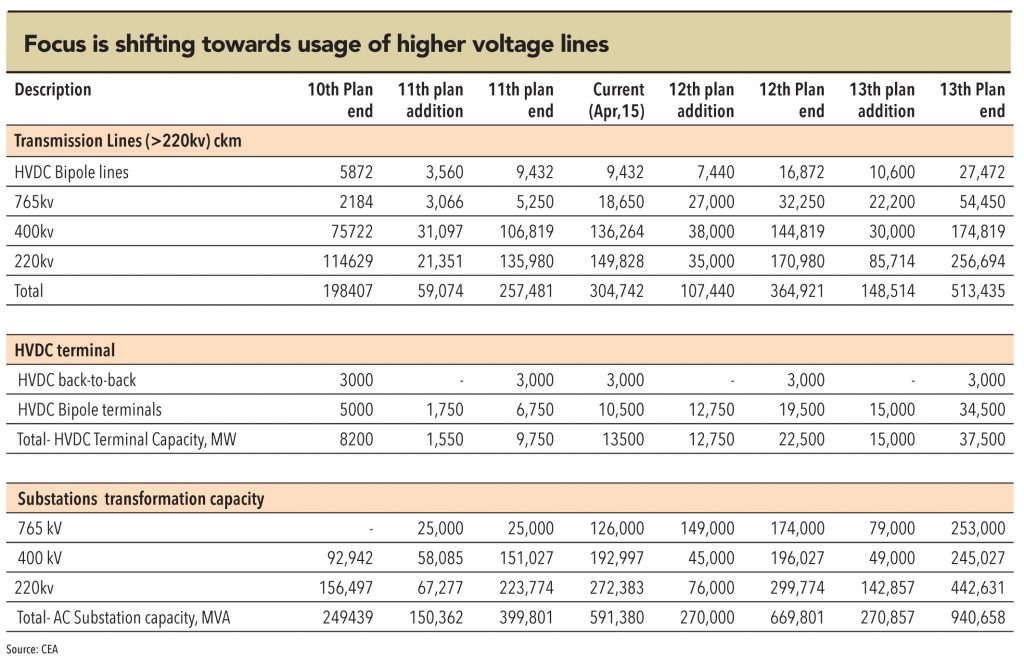

The Indian transmission network (>132kv) has continuously been moving towards higher voltages and new technologies. This has become more pronounced after the blackout in the northern grid in July 2012.

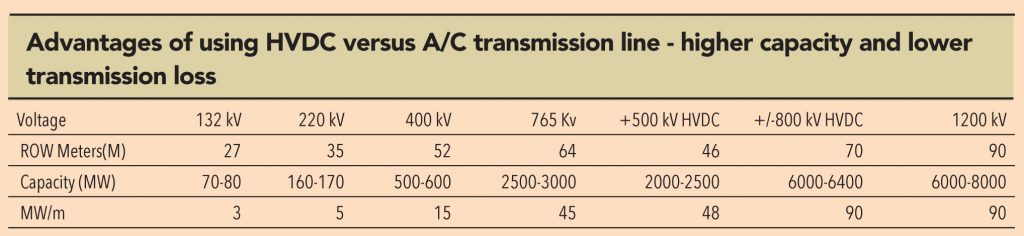

Currently, transmission lines are primarily run at 400/765kv voltage levels and PGCIL intends to move to 1200kv in the 13th-14th plan. Higher voltages lead to more efficient transfer of power while using lesser space.

New technologies that are being adopted to make the grid more reliable and efficient include HVDC, dynamic reactive compensation, PMU/PDC-based synchro-phasor technology/wide-area monitoring system (WAMS), phase shifting transformers and series reactors, and 1200kV UHVAC. Here are a few details of these technologies:

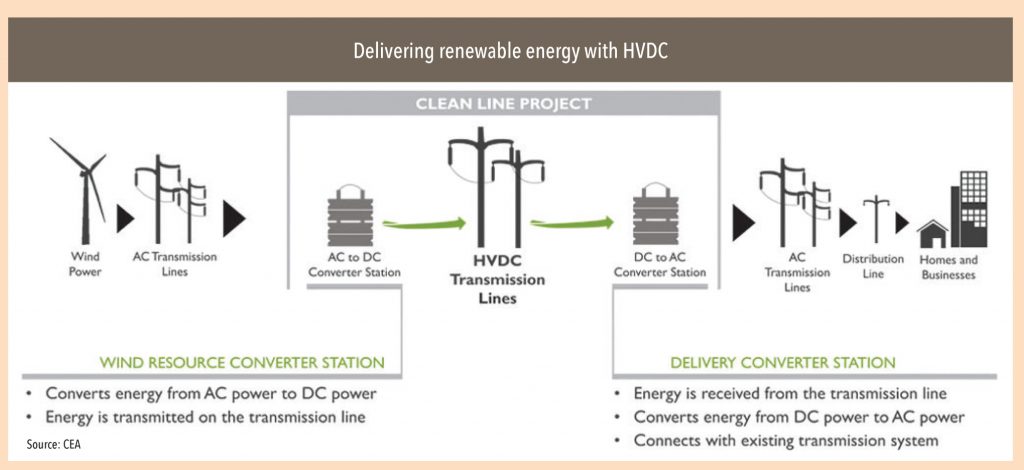

a. HVDC-based: A high-voltage, direct current (HVDC) electric-power transmission system uses direct current for the bulk transmission of electrical power, in contrast with the more common alternating current (AC) systems. These HVDC systems may be less expensive for long-distance transmission and suffer lower electrical losses. Since high voltage cannot readily be used for lighting or motors, they need to be reduced at the transmission level for end-use equipment. Transformers are used to change voltage levels in alternating current (AC) transmission circuits. However, most HVDC systems have thyristor valves (a small device used to control high voltage) and such HVDC systems are also called line-commutated convertor (LCC). A long distance point-to-point HVDC transmission scheme generally has lower overall investment costs and lower losses than an equivalent AC transmission scheme. HVDC-conversion equipment at the terminal stations is costly, but the total DC transmission line costs over long distances are lower than AC lines over the same distance. Further, HVDC scores higher on controllability front, as power flow between AC systems can be automatically controlled without risk to the network.

b. Dynamic reactive compensation (SVC/STATCOM) – In order to maintain voltages within stipulated limits and grid stability, STATCOM/SVC are required as dynamic compensators at strategic locations. A static synchronous compensator (STATCOM) is a regulating device used on alternating current electricity transmission networks. When connected to a source of power it can also provide active AC power. Usually a STATCOM is installed to support electricity networks that have a poor power factor and (often) poor voltage regulation. While it does have other uses, the most common use is for voltage stability. A static VAR compensator (SVC) can also be used for voltage stability. However, a STATCOM has better characteristics than an SVC on the grid-stability front due to its ability to maintain current output irrespective of voltage levels.

c. Synchro-phasor technology/Wide Area Monitoring System (WAMS): The Indian power systems’ dimensions and complexity is increasing. This necessitates better visibility of the grid system. To achieve a safe, secure, and reliable operation on a real-time basis, it is necessary to rapidly update the operating scenario with intelligent computation to capture the dynamic behaviour of a power system. To address critical developments in the grid application of synchrophasor technology using Phasor Measurement Unit (PMU) along with Phasor Data Concentrators (PDC) and high-speed wideband fibre optic communication links are used. The dynamic behaviour of the power system can be observed almost real time at the control centre, thereby improving/enhancing situational awareness for the operators and helping increase the grid’s deliverability.

d. Phase Shifting Transformers: Existing transmission systems are often operated and stressed to the limit of the performance capability of their original design, in order to maximize asset utilization. To ensure that under these conditions the grid’s operations remain economical, reliable, and secure, the need for various aspects of power flow management within the power systems is becoming evident. Phase-shifting transformers (PST) help control the real power flow in transmission lines and systems inter-ties. They allow for better utilization of existing networks by balancing the loading in parallel paths.

e. Series Reactor – To meet the growing power demand generation, new lines are being added. All this has resulted in an increase in short-circuit level. In India, as generation resources are concentrated in selected areas, these locations face high short circuits. Similarly, areas with high demand, connected by many lines, also face high short-circuit levels. Series reactor has been considered for limiting the fault current level and therefore the resulting short circuits there from.

f. 1200 kV UHVAC technology – In India, in the past decade, 765kV Extra High Voltage (EHV) AC technology has been on the forefront of establishing high capacity transmission corridors. However, in view of the growing right-of-way concerns and establishment of gigawatt- scale generation complexes, there is a need for further increasing transmission of power in a given right-of-way. In this direction, the world’s highest transmission voltage level of 1200kV UHV-AC has already established in India with the charging of National Test Station at Bina in MP in 2012. This technology has been developed indigenously through the establishment of a 1200kV test station through a collaborative effort with leading Indian electrical equipment manufacturers, CPRI and CEA and Powergrid. The technology is expected on a commercial basis in the 14th plan (2022 onwards). After getting adequate experience in the operation of 1200kV lines and substation equipment at the test station at Bina, and based on system requirement for bulk transmission of power, more 1200kV lines could be planned. However, in case of low power transfer requirement in initial periods, lines may be operated at lower voltage levels.

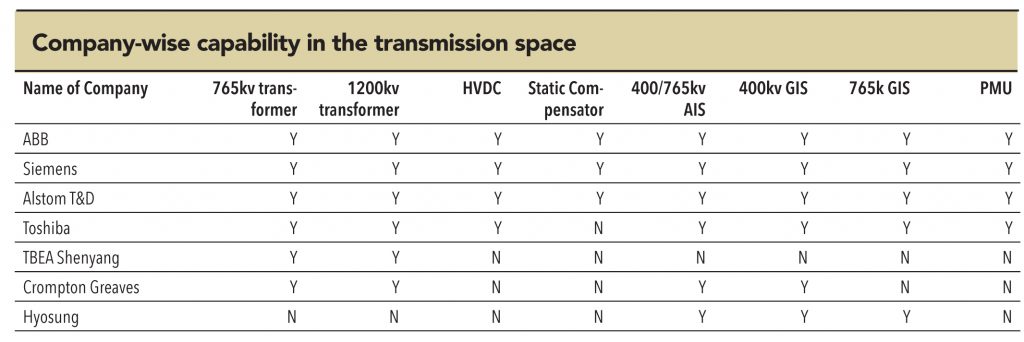

With most of the incremental transmission capacity likely to be put up at high voltages, the player-wise capabilities across various equipment types are listed above.

“Make in India” clause by PGCIL

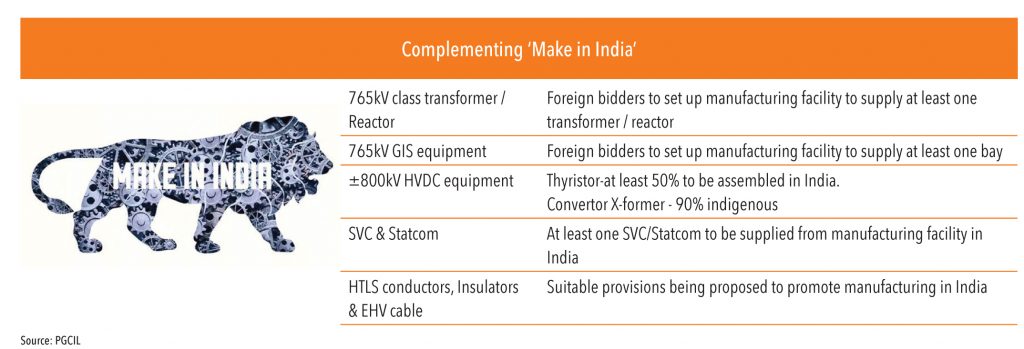

In order to promote the government’s ’Make in India’ initiative, PGCIL has already put in place stringent norms to force equipment suppliers to set up factories in India. Even before the current government’s push, PGCIL had inserted a domestic manufacturing clause for its 765kv transformers. This in turn led to companies (Alstom T&D, Siemens, ABB, and TBEA Shenyang) setting up factories at Baroda over the last 5-6 years.

As highlighted in the chart below, PGCIL has expanded the domestic manufacturing clause across equipment types; this will lead to more Chinese/Korean companies setting up shop in India. Channel checks indicate that Baoding (Chinese transformer manufacturer) has started constructing a 10,000MVA transformer facility at Baroda while Hyosung (Korean GIS manufacturer) is putting up a factory at Pune.

The Make in India clause benefits local players in two ways:

a) It weeds out non-serious players who were previously importing and dumping equipment from their overseas factories. This is in turn implies a bigger pie for existing players and is very evident in the case of 765kv transformers where Koreans have completely left the market after PGCIL imposed the domestic clause.

b) Improves pricing for locally made equipment as the domestic players have a more level playing field versus foreign competition (read Chinese and Korean players).

Subscribe to enjoy uninterrupted access