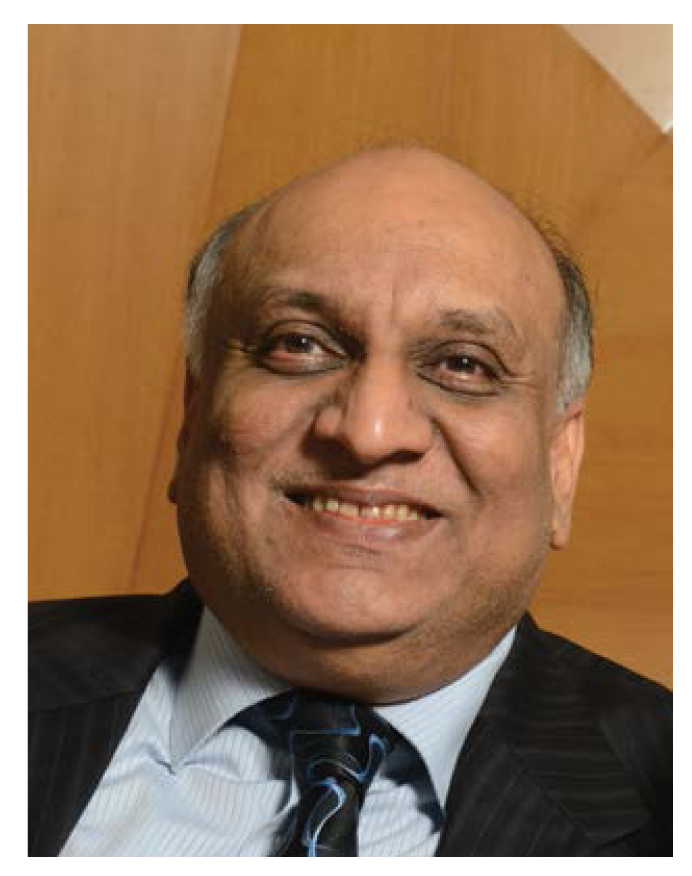

In a two-hour interview, Mr. Hari Mohan Bangur, representing the third-generation of the Bangur group, and currently the Managing Director of Shree Cement, talked about a variety of topics related to his company and the industry.

Mr. Bangur is a Chemical Engineering merit-list graduate from IIT, Mumbai, 1975 batch. He has been in charge of Shree Cement from 1st August 2002 during which time the company’s market cap has grown to Rs 583bn (based on Shree Cement stock price as on 27th February 2019) from Rs 1.56bn and sales have increased to over Rs 100bn from Rs 4.5bn. Today, Shree is among the top-five cement manufacturers in India with an annual production capacity of 38 million tonnes. It also ranks among the top-100 companies in India in terms of market capitalization. Mr. Bangur was chosen as the EY Entrepreneur of the Year in 2016 and was named Entrepreneur of the Year in 2017 by the Forbes India magazine. He is currently the President of Rajasthan Foundation Kolkata Chapter, ex-President of the Bharat Chamber of Commerce & Industry, and Executive Member of FICCI. He was the President of The Cement Manufacturers’ Association (CMA) from 2007 to 2009.

Besides excellence in business, Mr. Bangur’s passions include managing and overseeing the philanthropic activities of the group, particularly in the field of education, charitable hospitals, and social welfare trusts. He is involved in helping senior citizens of Kolkata by contributing substantially towards old-age home and by setting up ‘Pronam’, an NGO that provides a 24-hour helpline for Kolkata’s elderly.

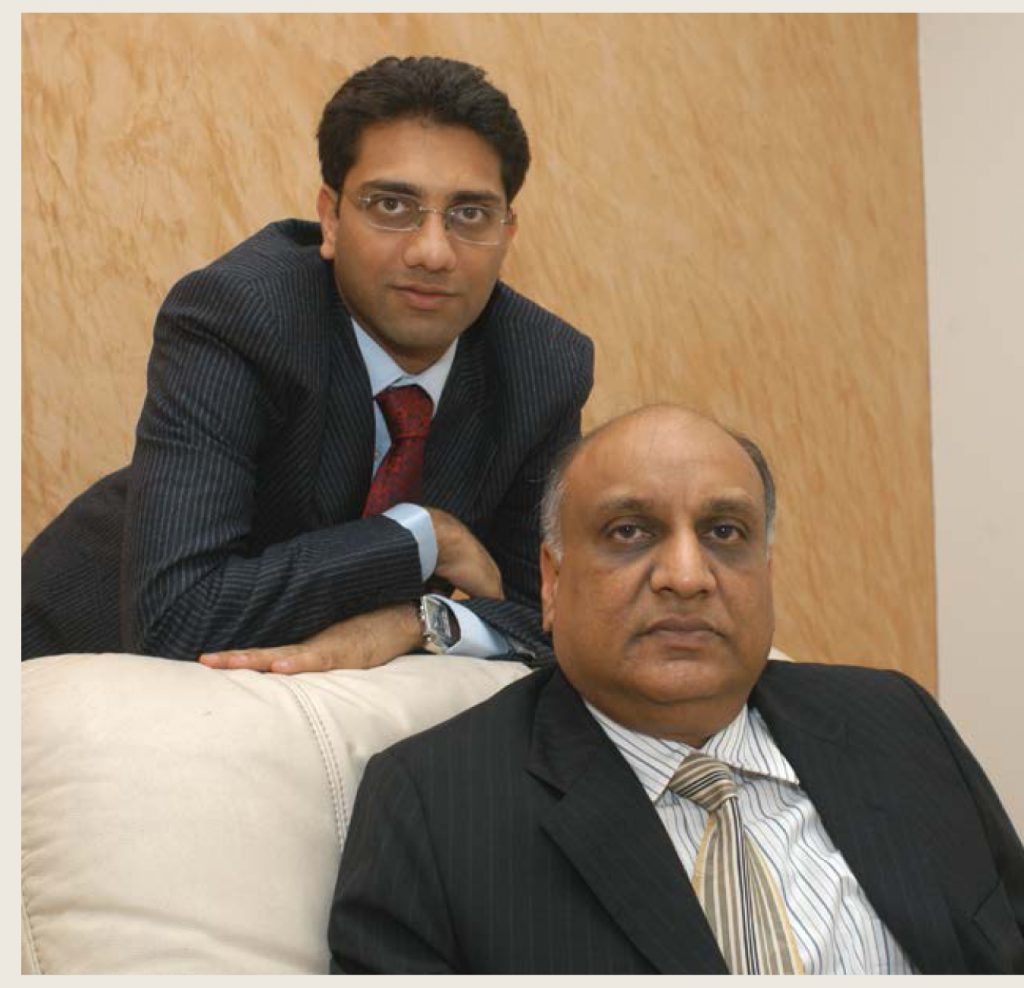

HM Bangur took over Shree Cement’s reins from his father Mr. Benu Gopal Bangur. BG Bangur currently serves as the Chairman of the company and is ranked 22nd on the Forbes list of India’s Richest People with a net worth of US$ 5.4bn. HM Bangur’s son, Prashant Bangur, joined Shree Cement in 2004 and presently serves as the Joint Managing Director of the company. He has been a strong support to his father and has played an instrumental role in technical innovations, contributing substantially to the company’s growth. Under their combined leadership, Shree’s annual capacity has increased by more than fourteen times from 2004. Its Waste Heat Recovery System is the largest by any manufacturer in any country in cement industry (excluding China). Their leadership has also led to Shree Cement being declared ‘Sustainability Champion’ in cement industry by the World Sustainability Forum in September 2011.

Prashant Bangur has followed his father’s footsteps on business federations and in terms of social and philanthropic activities. He is a senior member of various reputed commerce and educational institutions including National Management Committee of Cement Manufacturers’ Association, Indian Chamber of Commerce, Kolkata and Bharat Chamber of Commerce & Industry, Indian School of Business, and TERI University.

“I relied more on their judgment rather than mine. When you are in management, sometimes you are distracted by short-term problems.”

A. Definitely, sixth sense comes because of some knowledge. We were losing money and interest cost was roughly 10% of turnover. If interest cost is 10-11% of turnover it means very soon the company will be finished. The cement industry was never very profitable, and the absolute profitability per tonne was continuously falling. At that time, I thought, a foreigner coming to India for the first time who doesn’t know India (but has done detailed homework) is ready to give me so much money – it means he has seen much more value than me.

French people are generally more conservative than others, and despite this mind-set, they were still willing to give me so much money. This implied that they had seen deep value. So I relied more on their judgment rather than mine. When you are in management, sometimes you are distracted by short-term problems. This gave me a new angle – I thought let me try for one more year because if my decision went sideways, instead of x amount of money, ‘x-10%’ would always be available. I thought, I am taking a risk of 10% – let me try for one more year. Things started getting better almost immediately – we turned the corner.

A. The biggest risk in business and when you are weak is when you convert your short-term liquidity, or liquid assets into fixed assets. At this time, you are the weakest. At what speed should fixed assets be created, and at what cost of liability – that is the key, as ultimately asset is equal to liability. Generally, people would only like to see one side of the balance sheet – the asset side – but an equal liability is also being created. Does our company have enough momentum to take the liability or not? That has to be judged.

“In chess, you normally lose the game when you try to become more aggressive than your position warrants. It’s the same in business.”

In chess, you normally lose the game when you try to become more aggressive than your position warrants. It’s the same in business. If you take more risk than your position warrants, sometimes you succeed because of a favourable wind, and sometimes you fail. I like to take into account some headwinds and proceed accordingly.

A. De-risking in any business is not about cutting costs. For de-risking, the first thing is to have financial strength in place to tackle contingencies – so you ask yourself – how much do I have to grow, and what kind of financial strength do I want to have in conjunction with this growth – because any problem in business will be generally short term. If the market is very bad, three or four companies will cut down production – and the market improves. It is a matter of 2-3 years of pain, after that, good times will always come. No industry will ever die. Our benchmarking should now be against international standards – how does our quality compare with international quality? Right now, Indian quality is not as good as the accepted international quality.

“De-risking in any business is not about cutting costs.”

Apart from this, it is energy costs – here, we are better than the world average. In terms of logistics costs, a lot of work has to be done; also in terms of the way we are delivering cement. Most of the cement is being used for concretization, but still more than 90% is bagged – which is totally different from what happens in the rest of the world.

A. Short term is say 1-2 years. In this timeframe, there is excess capacity, and I don’t see very robust potential. Profitability will remain at about Rs 800-1000 EBITDA/tonne for good companies.

In the long term, we don’t have enough limestone reserves. The way we are growing, the production that we would need will be difficult with present limestone reserves. Production would need to double in 10 years’ time, assuming the normal growth rate of the cement industry. Roughly 600mn tonnes production or a little more, would be required 10 years from now. This will be difficult, as new greenfield plants are not coming up at the speed that is required.

In the even longer term – after 10 years – the industry is likely to be very healthy. Because of the industry’s low cost structure, imports do not happen. Also, as logistics costs are too much, we are insulated from outside forces. The long-term potential of the cement industry is very good.

A. At that time, it was not a difficult call, because we knew for sure that if the experiment fails, we will die in 6 months, but if we don’t do the experiment, we will surely die in a year. Instead of sure death after one year, we chose the possibility of a long life rather than death after six months. It was a desperate situation but our risk-taking was well rewarded. At that time, Reliance also supported us, because it was in the process of creating a new market. Overall, the price of fuel (of petroleum coke) was nearly 40% less than the price of normal fuel – so it was worth taking that risk. Risk reward ratio was well rewarded.

“It was not a difficult call, because we knew for sure that if the experiment fails, we will die in 6 months.”

“We always wanted to do better than the previous year and better than our own earlier performance.”

A. I will not say whether we are the most valuable or not, but we never wanted to be number one or two – because the outside world was never a parameter for us. We always wanted to do better than the previous year and better than our own earlier performance. In this process, we first started with the idea that our cost should be minimum. In the process, the quality was just above what was then required by Indian standards.

Then we realized that as we are growing, we have to improve quality – because with low quality things will not work. We started continuously improving our quality, and that journey is still on-going. Now our quality is far better than it was in the past. Earlier, we believed that there is a shortage in the market and that more production will work – so we pursued that policy. Now our policy is to have better quality, and this will always be at some cost – we are ok with that.

A. No, the challenge has to be created. First, you fix a target. Instead of say 10 productivity of the kiln (tonnes per cubic meter or kiln volume) which is the world’s best, we were at 9.5. We wanted to challenge ourselves to get this to 10.5. If the normal was 6, we would set a target of 7 or 7.5 for ourselves. As soon as we reached near our set target, we would set a higher one

“The challenge has to be created – Profitability is the by-product, but doing correct and innovative things is more preferable.”

The biggest advantage of this is that in a commodity industry, there are no challenges for commercial and technical people – they do the same thing, day in and day out. Giving them a new challenge everyday keeps work interesting; everybody is highly motivated to achieve something. Profitability is the by-product, but doing correct and innovative things is more preferable.

A. Mr. Narotam Sekhsaria of Gujarat Ambuja is the father of the modern cement industry. He transformed the industry in many ways. Earlier, it was a distribution set up, no marketing. He was the first person who started advertising and who thought and taught us that marketing is also important, brand building is important, and he got results almost immediately. He was highly innovative and was in expansion mode. Earlier, all licenses were processed by the central government and they gave the license to Shree Cement, Raymond Cement, and Gujarat Ambuja Cement – all three on the same day and in the same meeting. We started our journey together. Gujarat Ambuja and Shree had different trajectories. Raymond Cement could not fly long – the plant was set up, but then it had to be sold. Since those three licenses were received on the same day, it gives me great pleasure to compare Shree Cement with Ambuja Cements (erstwhile Gujarat Ambuja Cement) – we always thought that they are far ahead. So yes, Mr. Narotam Sekhsaria is my role model.

Mr. Narotam Sekhsaria is my role model and Mr. DN Tiwari and Mr. Mahendra Singhi are two people whom I recall as my constant support.

A. Shree Cement fundamentally had two chief executives who were with us for a long time. The company was set up by Mr. DN Tiwari, who was from JK. He was the initial person who taught us the value of setting up the plant at the lowest possible cost and technological excellence. He did a lot for the company and then he retired. When we wanted to set up our second unit at Beawar, about 10 years after he retired, I called on him. But he said “leave me” (laughs). I insisted though, because I thought that he was the best person available. I told him that he would only have to set up the factory, and we will get someone else to run it. Being a project man, he agreed and he did a wonderful job – both times – in his first phase with the company and also when he agreed to put up the second unit.

The second person who was there for us for about 18-20 years was Mr. Mahendra Singhi – he gave the company many new dimensions. Naturally, with time, everybody has their own priorities – but he left us on a very good note.

A. Fifteen years ago, we faced a debacle – when we had over-borrowed and had to see that how we are saved. An unnatural risk was taken and the headwinds then made the risks more severe. After this, we thought that it is not worthwhile taking risks. We increased capacity without being aggressive and without taking loans and till today whatever money is generated, we put it back and our capacities are largely created through internal accruals. So our capacity addition is not aggressive in the financial sense. However it looks aggressive to outsiders because of good growth and because we were putting up capacity at a low price as we were obviously cutting costs somewhere. As a result, our plants were compromised somewhat – but this proved to be wonderful for us.

“It was a natural speed for us, not an aggressive one.”

Once the plant was up and started making profits, we invested more money and upgraded our plants and made them up to date. In this scenario, our capital cost was low and our stores cost was a little higher, because we would change whatever was second grade immediately. This situation continues even today for us – our capital cost is low but our stores cost is little higher because we continuously upgrade spare parts. Basically, it was a natural speed for us, not an aggressive one – others may perceive it as aggressive. I have never been and would never like to be aggressive.

A. Our model was a little different. We have set up 8 kilns at Ras – most are similar in terms of capacity and same model. When people were asking for 3mn tonne capacity we were putting 1.5mn tonnes. After sometime, when there was enough clinker capacity at Ras, we then chose to increase our capacity marginally for the last couple of kilns. We make the same purchases, the same machines, and same models so that everything, including spare parts were common, and so that the learning from one kiln can be transferred to other.

A. Of course, raw material is one reason. However, when we took over the mine, the quantum of limestone was not yet explored. We explored it, and found that it can support us for 40-50 years and we kept adding capacity accordingly. Now Ras cannot take more capacity.

A. Shree Cement is a highly professionally managed company with a lot of power given to various people. The real problem in the industry or any factory is that there is a mismatch of knowledge and power. Those who are knowledgeable normally don ’t have power and those who have power are not as knowledgeable as they ought to be. In our company at the top management level, the important thing is to first get more and more knowledge about the market, about technology, and about the industry. This then helps to identify, understand, and solve the problems at various levels. Only board-room activism is not enough.

“Real problem in the industry or any factory is that there is a mismatch of knowledge and power. Only board-room activism is not enough.”

The most important thing – from now to even ten years later– is to become more knowledgeable at the top level; the second is to bridge the gap – that is, to empower functional heads and heads of the department. They need to have total ownership of their own department – and with that much power, they have to work. External checking has to be reduced.

These are the changes I will like to see in the next 10 years and this is what we want to do. Our growth policy will continue. Shree Cement will grow naturally, without taking on much debt. We may take small debt at times, but basically growing without taking debt is our number one priority. The second policy is that Shree Cement will always remain only in cement business. We wouldn’t like to go into any other business. If the promoter family wants to do so, which seems unlikely, we would float another company. Shree Cement will not have a subsidiary for another business; it will always remain focused only on cement

A. Our experience is good, but it is too early. We have acquired Union Cement only seven months ago. We would wait and see how things move along for 3-5 years and only then would we decide if this is giving us good return on equity and whether we are able to give enough back to Shree Cement’s shareholders. Nearly seven months have gone by – we think that for another 12 months, the profit generated will be ploughed back and only then would we start getting dividend from the asset. We will study our experience at that point and then take a call on the future.

For the first one or two years, all acquisitions needs extra money and capital expenditure. As you want to run the plant, the philosophy of the previous owner may not be necessarily the same. For the first one year or two years, the cash flows will be invested back in the company and the money will then start flowing to Shree Cement shareholders as we see.

A. Ready-mix concrete is a possibility. But we review such business calls every three years or so. Last time, we took a conscious call that we are not going into this business. It is too retail a business, and we would not be in it – we are supplying cement to ready-mix makers.

A. Future possibility cannot be said yes or no. It is not in our focus currently, so for at least 2-3 years we are not going into it.

A. We had gone for Autoclaved Aerated Blocks (AAC). It seems to be the future, but our past experience has not been very good. The unit is now making a small profit against a loss earlier. We are not going to get into another business, as I said.

“Course correction is never easy because for that you need some extra energy.”

A. Course correction is never easy because for that you need some extra energy. Therefore, we are going very gradually. We are sure about the direction – that our realisation will gradually increase compared to peers. Market forces apart, our realisation will increase per quarter by 1-2% because small shifts will take place.

We also plan to introduce a premium brand in north and east India. For the south, it is still too early. It is hardly a couple of months. So we would taste the market before we do anything. These are the directions we are working on. Challenges, well of course it will not be easy – running on the same track is easy, but for changing tracks, you have to spend some extra energy.

A. Yes, of course, but the effect will be visible only after some time. We are going through the exercise – we are preparing ourselves. Before one builds a building, the foundation needs a lot of work. We have started it – and results should be visible may be after a year or 10-12 months. Lot of work is being done. You will appreciate it little later.

“Before one builds a building, the foundation needs a lot of work.”

A. Innovative product means a premium brand. One that is much better naturally than the current product.

A. Everybody has to make their own wealth. No generation can pass on wealth to the next generation – every generation has to work hard and find their own success formulas. Old formulas will not work for long, that’s for sure. So he has to evolve, he has to have his own captains. Hard work and smart work are the constants that I would like to pass on to him. Rest everything is upto him.

A. No. He is much better than me in many aspects, because he has been brought up in the present atmosphere – he understands it better than me. Therefore, inculcating my values is not a formula for success; that was a formula for success for my generation (laughs). New generations will have new success formulas. Copying any senior is the surest way to failure. Having my value systems is the last thing I would want for Prashant.

“New generations will have new success formulas. Copying any senior is the surest way to failure.”

A. Hard work and smart work. But more than that, respecting all people, including colleagues. The minute you insult someone, you lose your own prestige and respect. Whenever you rebuke anyone or whenever you try to demean anyone, you lose your respect. He knows this. I am not saying one should never get angry, but your anger should not demean anyone. This one attribute will hold you in good stead in the long term and Prashant knows this well.

A. ESOPs are one way to retain people. But I feel that giving opportunities to work is the biggest gift and challenge you can provide. All people like to have their capabilities challenged – if we give them enough challenges, then there is enough motivation. Money, at a certain level everybody gives; ESOPs are nothing but a form of money. But apart from money, the challenges and opportunities to grow professionally that you provide makes a difference. Our past record show that in the last 10 years, hardly 10% of our people above a certain rank have left. Our stability is high and that is all because of new challenges that our team takes upon itself. Ours is an open field – anybody can come and work and even if he they don’t work, they can survive. However, they won’t get respect.

A. I would like the government to work more on infrastructure development. Fiscal incentives to the industry do not mean anything. Expanding the market, which subsequent governments have continuously done, is very positive, and with time, this will speed up. India needs lot of infrastructure growth. No other changes are needed I think. I am quite happy with the way the government is working and the industry is working.

“Prashant is much better than me in many aspects.”

Q. So internally, you don’t think any changes are needed in the industry?

A. Internally, the only challenge that exists and which is permanent is that everybody wants to grow – and this will always be the challenge in any industry. That growth can come only at somebody else’s cost. The total market share is 100 – and everybody will try to take more for themselves. The Indian industry is doing fine. We have to now see how the international industry works and we have to be at par with them or better. Having said that, our industry, even presently, is above international standards as it is new. So no other changes are required.

A. The government can be clearer about allotting mines or the process of getting mines. Right now, mines are auctioned without the government purchasing land. If this changes, i.e., the government purchases land before auctions, not only will it get a lot more value, but also things will move faster for the industry – everything will be smooth. That way, the industry can start working on their project from day 1, all environmental clearances can also be faster, and a lot of time will be saved. This will help Indian money to be used in a better way. Right now even after investing, before the money comes into play it is 3-4 years. This can be made faster.

A. The real-estate sector is a very small factor for the cement industry. It is only in few big cities that the real-estate sector has a big play. Otherwise, for us, 90% of house building comes from towns and cities such as Bareily and Mathura where real-estate players are not present. Living in cities such as Mumbai and Kolkata we tend to think that the only way to own or build a house is through real-estate developers. But in reality, individual house builders with their surplus money are the driving force. The organized housing sector is a little weak presently (it is facing a cash crunch) because it grew too fast. So factors that were giving them unnatural growth earlier are giving them pain. This sector had benefitted three years ago.

A. We don’t know how the government will generate enough money for infrastructure projects. As I see it, in the budget, capital formation has increased only by about 5%, which is a little lower or almost equal to inflation. There is no extra space for capital formation. Distributing money to the public means public spending, which is good and needed, but capital formation is also essential. However, I am not an expert – the best brains within the government are working on this, and they must have done whatever is best for India.

A. These are very short term issues. We are looking at 10 years or beyond – say 30 years. In that case, six months here and there does not matter. They (events) are immaterial.

A. India will grow because everybody wants to improve their lifestyle. Here in India our people are very hard working throughout the week – from morning 8 am to evening 8 pm. The Indian story is one of 7% growth, irrespective of the government. So there is nothing ‘adverse’ – whichever government comes.

“We must not challenge the collective wisdom of Indian people.”

A. Coalitions are also good. We must not challenge the collective wisdom of Indian people. If this wisdom is in favour of a coalition, then it must be good. I always believe in democracy. Our democratic forces are strong.

A. Demand growth is one thing, but it has to harmonise with capacity utilisation. Demand growth is usually calculated over the last year, but if you have enough additional capacity, then the additional demand growth does not mean much. Our capacity utilisation has not yet touched 75%. Until the industry reaches 75-80%, price increases will be difficult.

A. Yes. Right now we are facing some shortage of clinker. Coming from the bottom side of the price, it takes extra time for the price to increase. When you are coming from the upper side with the same demand growth, good times will continue for six more months. In the present scenario, for prices to fall will be more difficult and when they are down, rising will be difficult. Maybe in this summer or 4-6 months we could see some price increases as we are already seeing some clinker shortage. It will re-correct itself.

A. Competition must compete and it should be there. But everybody has a different mindset and is at different stages. Everybody must do what is best for themself. We are in a different phase – we want to improve quality. Somebody might want to improve volume. Others want to change something or start innovation – everybody has their own needs. Some are facing cash crunches and they want money quickly. So how can we advise anybody? Everybody in the industry is a high-class professional and they are running their companies in the best possible way.

A. We are learning a lot from the not so well known and comparatively weak Union Cement, which we have bought. A different culture provides a learning experience. We are learning how things can work with lesser people, more responsibility given to people, and less bureaucracy in internal systems. In India we have too much of bureaucracy. The ratio of working active people on the floor to non-active working people in the office is skewed – non working people in the office can be reduced. India has to learn better management size from its competitors. Technically, we may be better, but we can adapt in terms of a smaller management size. Also, ‘how to fix responsibilities’ is something that we can learn.

“India has to learn better management size from its competitors.”

A. We are doing our best. In a commodity industry, nobody knows that will happen tomorrow, but we will work with the same philosophy that has been ours for the last 15 years. New challenges will keep coming – the only thing that I can say with certainty is that we will always work with the same level of motivation.

A. Making friends with your competition is automatic when you attend meetings with them. It is not that those friendships are based on business relationships. You meet people, basically nice people. Also, people migrate within the industry or from other industries which you know. So for many people naturally acquaintance is there. Friendship is a very strong emotion; there isn’t a specific friend as such, but there are many good acquaintances.

A. Ramco Cement in south India is doing very well. We respect their innovativeness and professionalism quite a lot. And you cannot ignore UltraTech Cement – it is the biggest and it is the torchbearer of the Indian cement industry. It has roughly a 100mn tonne capacity right now, so it sets the pace. So, for size and a futuristic plan – I would say UltraTech Cement and for innovation and working – I would go with Ramco Cement.

“I admire Ramco Cement for innovation and working and UltraTech Cement for size and a futuristic plan.”

A. I think the Indian consumer will have lot of buying power and FMCG is one sector that I would put my money in – but as an investor and not a promoter. If you get the same return from a high-grade FMCG company, why run a company when you can get it as an investor (laughs).

A. Ah – youth of the nation! (Takes a deep breath) One adverse incident and they get nervous very fast. Difficulties and danger will always be there, but one must never lose heart. Everybody will advise this generation to work hard and they are intelligent. However, very few of them have seen truly bad times, so they should not lose heart when difficulties arise but think about how adversity is going to change them (positively) after three years. If they are able to see this, they will find that adversity is nothing. Failures don’t matter. The youth does not understand this. They have to take a little longer view and more important – their friends, parents, and guides should give them enough encouragement and positive feedback.

• Empowering others is number one and smart work is number two – but they go together because only with smart work you can empower others. Also, empowering others has to be done very smartly – choosing smart people.

• Other things are secondary. Sixth sense is the last thing because it is luck. You cannot rely on luck – sometimes it works and sometimes it doesn’t.

“Empowering others is number one and smart work is number two.”

• Family values and cultural values are always to be seen in a different way. All our families migrated from Rajasthan. So should we take that value when they took a risk and they migrated? This may be one set of family values. How do you interpret family values and cultural values is up to you.

• Getting a legacy is good but the old keys will not work because the locks are new. So you have to have your own new set of keys, which family values will not give. Hard work is always important, but working smart is more important.

A. If I am not at work then I have to enjoy! I believe everything has to be done only for two purposes. Any action, any activity should be either for pleasure or for profit. There is no third reason to act (chuckles). So if I am not working for profit, I am working for pleasure.

A. I will answer but my answer is going to be a little long. First, you have to understand that you have to do atmakripa – which is betterment of self – be determined for yourself and by yourself. The second is gurukripa – which is for the guide or philosopher or anybody senior to you – this could be your parents or people in the industry who want to help you. Third is granthkripa, which is your books and other things such as your knowledge. If these three are there with you, God’s blessings are not optional – he has to help you. So you won’t have luck if you don’t have these three aspects with you. But if you have these things, the fourth is automatic. God has no choice but to help you.

A. I play card games, mainly Bridge, and I play some volleyball. I also do some cooking.

A. I used to, but I stopped about five years ago. The reason I did it was that in management, you never know whether you have performed your best or not. Competitive challenges such as French Open, Wimbledon, which happens at regular intervals, will tell you who is number one. In business, you live on past glories – so how do you check where you stand? I thought if I can get about 85-90 percentile, then I am good.

HM Bangur’s average CAT score was 93-94 percentile to which we must add another 5 percentile for his experience making his total score as 98 percentile!

A. My average score was 93-94 percentile. Yes, this is a good score, but then I used to add 5 percentile for my experience because the experience also counts after all. So you can take my total score as 98 percentile! (smiles mischievously).

A. I don’t know exactly – but may be just Whatsapp which I use for maybe one hour a day. That’s all on the mobile.

A. Not as such.

A. Yes and no. I get personally involved at the time of choosing the activity and starting the activity, but then it is left to the professionals. I just take the first step forward – which project to work on, how to work on it, what to do – and once that is set, it is on auto mode.

A. Dal Roti.

A. I don’t see too many movies. However, I do like stories – so whichever movie has a good story, I will like that movie. No favourite movie or actor as such.

I don’t listen to music.

A. I don’t see much TV too. I prefer spending time reading books. I am more of a book reader.

A. Mainly management books. There are so many authors, so naming one favourite wouldn’t be right.

A. I dont watch many news channels either. I feel that being updated continuously is a lot of waste of time because whatever you are updated with now, within a few hours it is stale. Being updated once in a day at morning 6:30 AM by reading the newspaper is good enough.

A. Indian Express, Business Standard, and Times of India.

A. I prefer holidays abroad and prefer holidaying in Europe.

A. Normally I prefer blue 80% of the times. Red is our corporate colour though.

A. It sounds good. I have not yet thought about it but will definitely think over it. Maybe, by 2025 I will come up with a biography of Shree Cement if not my personal biography.

Subscribe to enjoy uninterrupted access