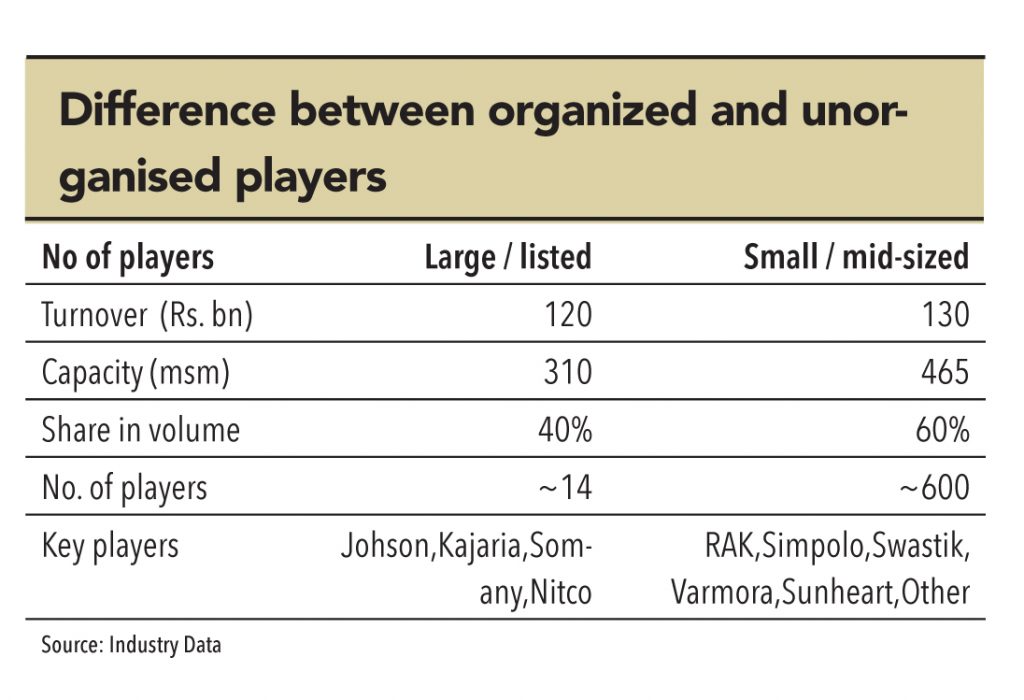

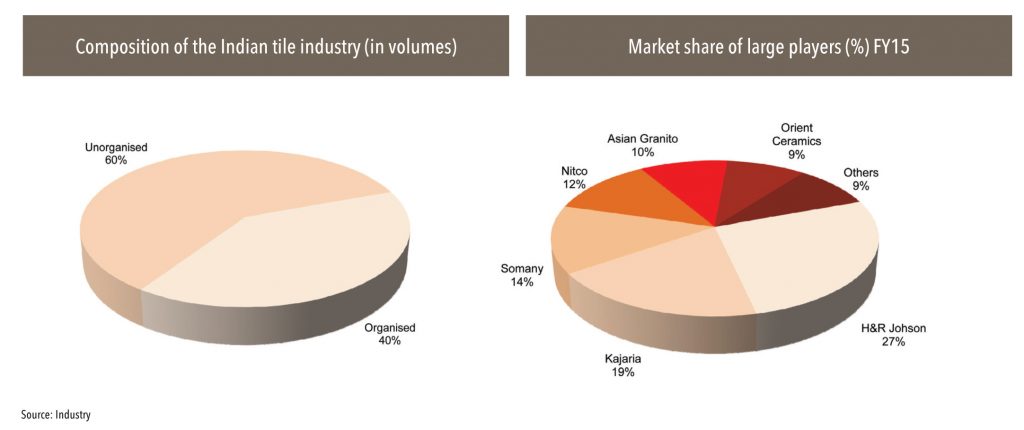

The ceramic tiles industry in India is highly fragmented with small and mid-sized players accounting for a large chunk of production.The larger (mostly listed) peers (~14 players) account for Rs 120bn (48% of total value). Within these, Kajaria, Somany, H&R Johnson, and a couple of other players are established leaders with an estimated share of ~40% of the total domestic production.

Mid-small players account for ~60% of the total industry (by volumes) – indicating the immense demand for tiles; 80% of these are located in the Morbi region in Gujarat – a production hub of the domestic ceramic industry. The town has ~600 manufacturing units, which includes ~60 large facilities of mid-sized players. The location accounts for ~70% of the total production of ceramic tiles in India, a large chunk of which consists of vitrified and polished tiles.

The output of India’s tile industry, classified along broad product lines consists of wall tiles (20% by value), floor tiles (23%), vitrified tiles (50%), and industrial tiles (7%).

While some of the significant manufacturers in Morbi (~60% companies) are currently classified as mid-sized players, their scale of operation and growth potential would see a change in classification over the next few years

Perseverance & focus, these mantras have enabled us to learn & grow

Its a typical, blistering April in Ahmadabad when we meet up with Mr. Girish Patel, CMD of Swastik Ceracon. Welcoming us with a broad smile and avuncular hospitality, he talked at length to the GV team about the evolution and current state of the Indian tile industry. Some excerpts of the conversation:

Sir, as a first generation entrepreneur, how did you enter the tile-manufacturing industry?

I come from a farming family and lived in a small village in Gujarat. I always had the desire to venture into manufacturing,which motivated me to try my hand at diamond crafting, followed by a photographic colour laboratory. When I got the chance to partner in a tile-manufacturing venture, I grabbed the opportunity. Spenta Cera Tiles Pvt. Ltd. was my first manufacturing unit, after which I branched out on my own and formed Swastik Ceracon.

How would you describe your journey so far?

Every stage of my journey has been a learning experience. In my initial years, I learnt on the shop floor about the intricacies of manufacturing and product costing. Rejection, production loss, and operating losses are concepts that I learnt first-hand in the factory. Then came cash-flow management and working capital. Along the way came lessons in manufacturing quality and customer management. Even today, I try to keep learning from my customers, my colleagues, and my peers from the industry. Learning is a never-ending process.

At Swastik Tiles, what instances would you recollect as turning points for your company?

While every moment has been special for me, I think one of the most memorable moments in our history was the commissioning of our vitrified plant in CY07. Another important milestone was the introduction of digital wall tiles in CY11-12, which put us on the global map. Lastly, our international supplies (Cengres Tiles), which started in CY13 was also a proud moment for all of us.

Today, what are the important facets of the Swastik Tiles brand? What is the USP of your operations?

We are known for providing high-end products with a lot of innovation, which offers a very high-value-for-money proposition.And for this, it is vital to be very cost-efficient and world-class in manufacturing.

Operational challenges today are quite different from a decade ago. Could you give some examples of this and how you surmounted them?

With the advent of ink-jet technology manufacturing, printing on tiles has become easy. By adopting the latest technologies,we have been able to increase the tempo of our operations and have migrated from the laid-back, artist-centric process, to a fast-paced technologically driven setup.

The Indian tiling industry is set for some good growth over the next several years. What is your strategy for capitalising on this opportunity?

In order to remain relevant, we have taken a conscious decision to invest in newer technologies. Simultaneously, we are expanding our marketing reach, not only in India, but also through the world.

What factors could jeopardise the prospects of the tiling industry in India?

Any untoward political situation, slower pace of reform or executive decisions, stagnation in the rural economy – all of these have the ability to hamper prospects.

As a successful entrepreneur, what future developments or changes are you preparing your company for?

I see overlapping of various technologies in the coming days to bring about novelties – which are not easy to match by conventional processes. I also see lots of potential in renovation and adoption of ‘green’ products by users. We, at Swastik, are always quick to adopt new technologies. Additionally, we are increasing our efforts in R&D, and are consciously going green in our operations. This would definitely help us to survive the onslaught of competition.

Subscribe to enjoy uninterrupted access