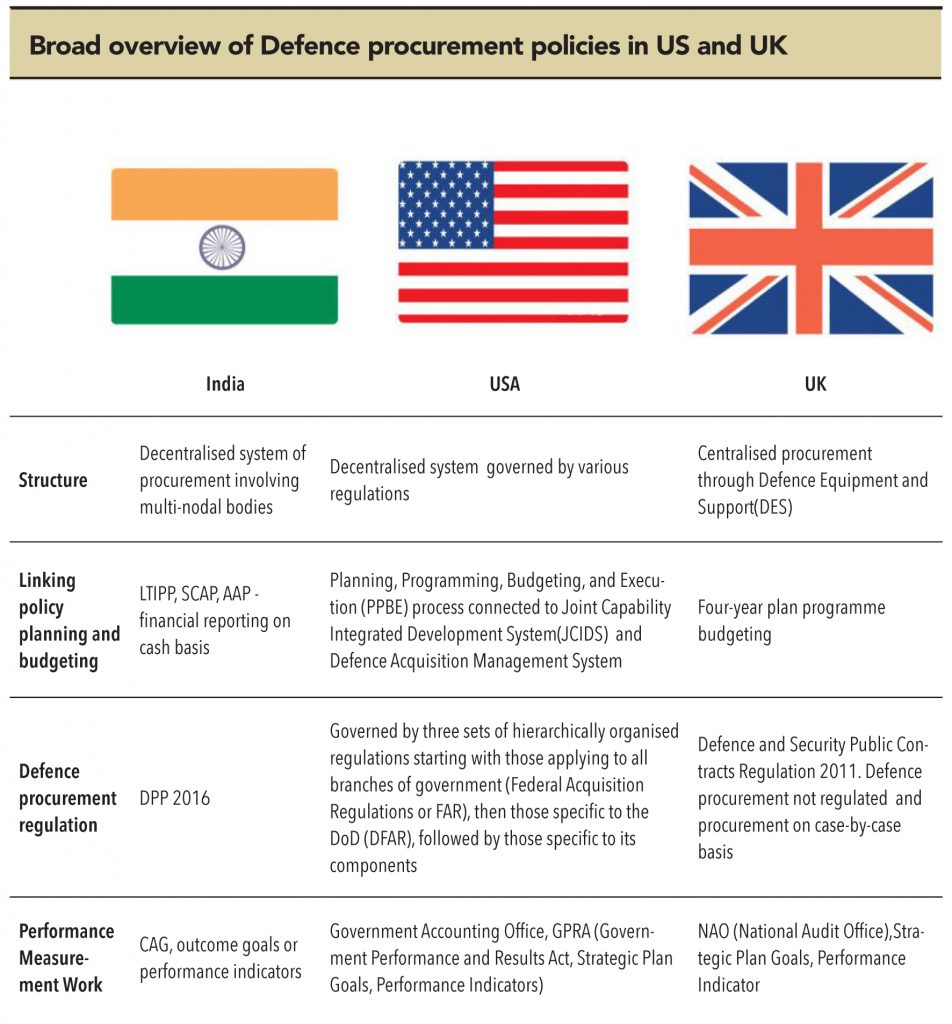

US and UK are one of the largest spenders on defence

Glossary:

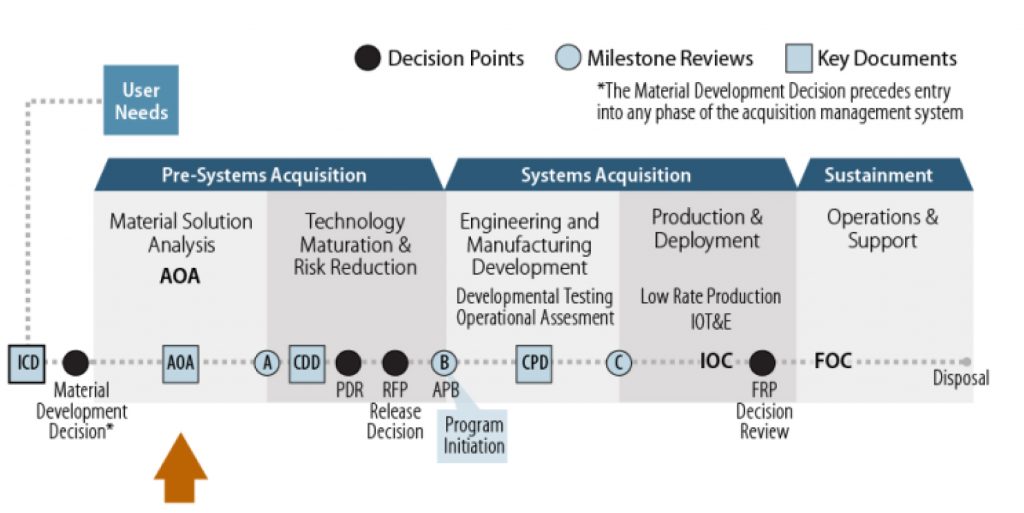

ICD- Initial Capabilities Document; AoA- Analysis of Alternatives; CDD- Capability Development Document; PDR- Preliminary Design Review; APB-Acquisition Programme Baseline; CPD- Capability Production Document; IOC- Initial Operating Capability; FOC-(Full Operating Capability

US’ defence acquisition largely involves three steps and there are no set timelines for each processes to be completed

• The Joint Capabilities Integration and Development System (JCIDS) – for identifying requirements.

• The Planning, Programming, Budgeting, and Execution

System – for allocating resources and budgeting.

• The Defence Acquisition System – for developing and/or buying the item.

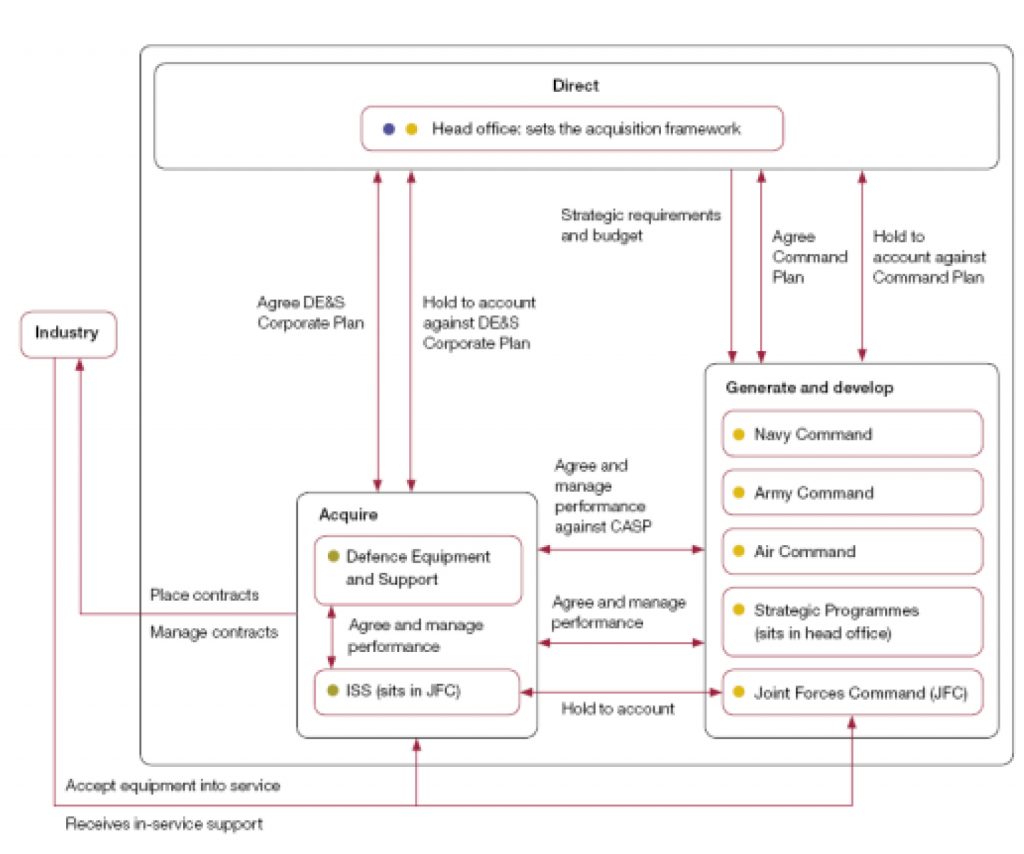

UK defence procurement procedure

The acquisition of defence equipment in the UK is based on the interaction between the Head Office, the armed forces (commands), and Defence Equipment and Support (DE&S). The Head Office provides strategic oversight while armed forces communicate their requirement. Defence Equipment and Support (DE&S) plays a critical role in procuring new military equipment, commodities and services, and supporting in-service equipment through life and managing global logistics operations. The Chief of Defence Material (CDM), who leads DE&S as its Chief Executive, is responsible for acquiring (procuring and supporting) equipment, systems and commodities needed to generate

military capability.

Analysis of both countries’ acquisition programmes (US and UK) indicates reforms in defence procurement remain a continuous process. Just like India, US and UK have had their share of difficulty in procurement programmes and cost overruns. Both countries face cost overruns in procurement

There is huge hue and cry about delays in the procurement of defence systems in India, but even developed countries (with perhaps more sophisticated processes for defence capital-equipment procurement) face problems too.

UK had undertaken ‘Successor Submarine Programme’ with an objective to replace its operational system of four Vanguard-class submarines. Based on MoD estimates, the cost of building four submarines has increased to £ 26bn in 2010 and £ 31bn in 2015, from an estimated £ 20bn in 2006. Preliminary studies on this programme started in 2007. The order for the submarines was to be placed in 2010, which was subsequently delayed to 2016. Only in July 2016 did the House of Commons approve the project with the delivery of the first submarine slated for 2028.

Similarly, the US has faced significant cost overruns in its ambitious plan of acquiring 2,457 F-35 planes and a Joint Strike Fighter by 2037. Work on the project began in 1997 and the first test aircraft flew in 2006. However, the first squadron was inducted in the US Air force only in late 2015. The price tag for this project is nearly US$ 400bn – almost twice the initial estimate. Initially, the country expected these planes to be operational by 2012; later estimates saw the first F-35s fully operational by July 2015, but these too have been delayed.

“The Ministry must have a realistic equipment plan if it is to strike a better balance between delivering the capability it requires and the taxpayer funds it has available.However, the Ministry’s track record in forecasting accurately the cost of its largest projects hardly inspires confidence. Between 2000 and 2012, the cost of its 69 largest projects ballooned by £ 11bn. Independent analysis in 2009 found that final project costs were typically 40% higher than the Ministry’s initial forecasts” – a statement from The Rt Hon Margaret Hodge MP, Chair of the Committee of Public Accounts, USA.

Subscribe to enjoy uninterrupted access