With increasing penetration due to easy funding, washing machines are at the forefront of the shift to premium detergents

Gone are the days when the family saved money for months or years to buy electronics items, when customers had limited options to choose from, and when they relied heavily on other peoples’ opinions to buy products. This is the era of the internet and customers do their own extensive research before buying electronics items. They also step into nearby electronics chains to get a feel of their shortlisted products. Buying decisions are also rapid – people can buy even expensive items on the spot through options such as EMIs.

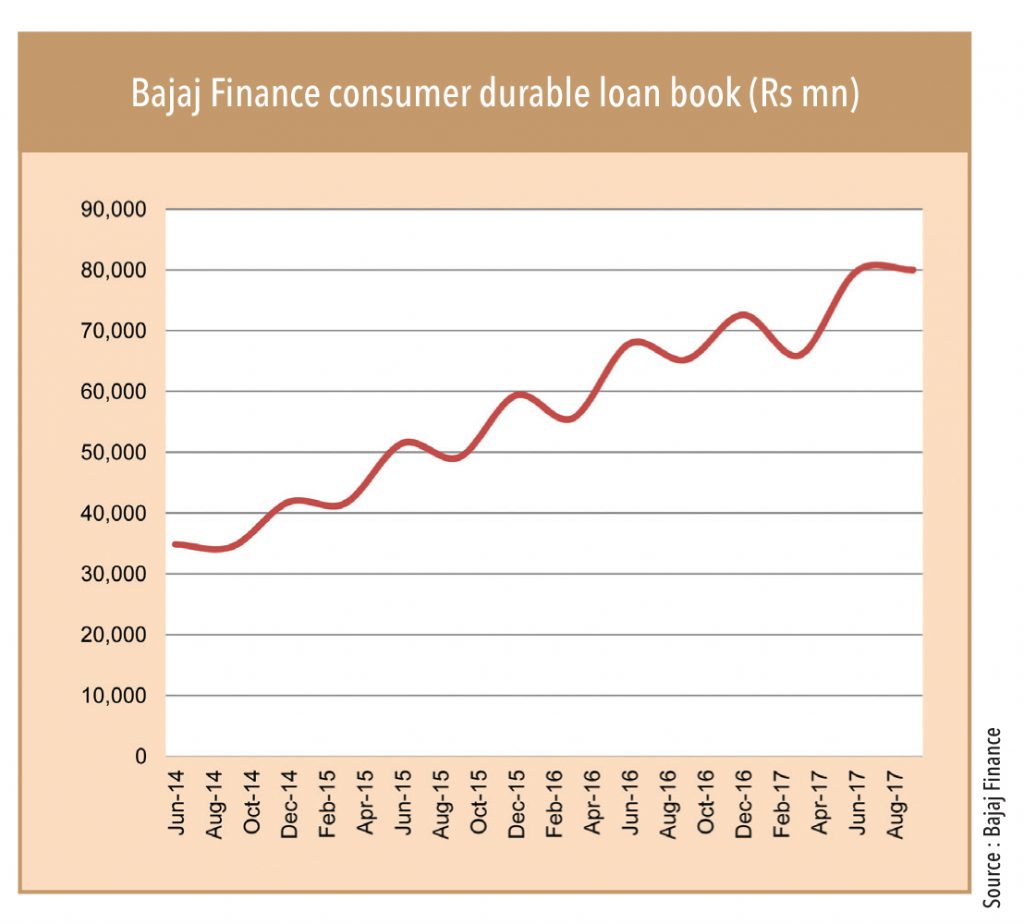

Easy availability of finance through NBFCs and credit cards with no-cost EMIs have changed things for the better in the consumer durables market. A strong credit bureau (CIBIL), internal data analytics, and strict checks and compliance by NBFCs for KYC through Aadhaar Cards have been able to rein in NPAs in this segment. New players (HDB Financial services, Home Credit, Capital First) have shown renewed aggression in tie-up with more dealers, making credit available in every corner of the country. Recently, Kotak and Axis Bank clearly stated their intentions of grabbing a larger pie of the consumer durable segment – which means sales of consumer durables are set to explode.

Machine penetration and product awareness = sharp surge in premiumisation

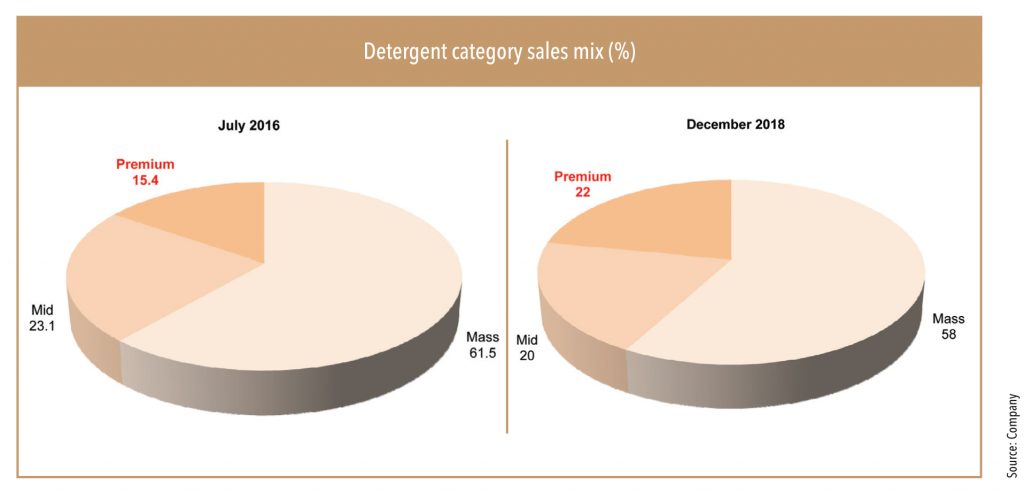

The reach of washing machines has increased with declining cost of ownership, increased availability of financing options, and resistance from domestic workers, at least in urban areas, to hand wash clothes. With more people buying machines to wash their clothes, they are also becoming more aware about the different types of detergents – normal, matics, and liquids. This knowledge is driving premiumisation. However, even as machine penetration increases rapidly, the adoption rate of premium detergents is quite gradual. This is because many are not willing to pay the premium for detergent powders that provide a better quality of wash and keep their washing machines in a better condition.

Washing machine companies are educating buyers through sales persons and technicians

There is hope. Washing machine companies, through their sales persons and technicians, have been advising customers to use matic powder to keep their machines in better working condition. Matics, they tell their customers, dissolve much faster with water and remove stains effectively. Liquid detergents, they advise, are the best product for washing machines, as they do not damage the machine as much as other products and they do not leave residue inside the machine.

Ganesh Pinge, 45, a mid-income resident of Dadar in Mumbai shifted to matic powder on the advice of a machine technician. “Shifting from Surf Excel Easy Wash to Surf Excel matic powder based on a mechanic’s suggestion has eliminated my problem of white stains and marks on my shirts, as the matic powder dissolves much faster in water,” he said. This is due to the higher presence of active ingredients in matic powders. “Moreover, my machine is working much better – has not broken down, and hasn’t clogged in the last three years,” he grins happily.

“About 1% of the FMCG market is moving from mass and mid-tier to premium every year. At an overall level, about 28% of the market is premium. Our aim would be to help consumers trade up,”

– Sanjiv Mehta, CMD, HUL in a newspaper article

For Shweta Mehta, 32, a resident of upmarket Kemps Corner, it was a crash course about detergents when she bought an IFB Automatic Front Load washing machine through IFB Point. She said she was ‘blown away’ by the deep understanding and knowledge of the manager at the outlet who told her all about appropriate washing machines, depending on what clothes need to be washed, and the intensity with which they should be washed. She said, “I have started using liquid detergent in my washing machine as liquid leaves no residue and increases the life of my machine. The quality of the wash is also far superior as liquid detergent dissolves easily and contains some amount of conditioner in it. When you compare matic powders to liquid, the effective cost, at least for me, is somewhat similar.”

Machines are key drivers of premium detergents

In the book, “23 Things They Don’t tell You About Capitalism”, economist Ha-Joon Chang made a provocative comment: “The internet revolution has (at least as yet) not been as important as the washing machine and other household appliances, which, by vastly reducing the amount of work needed for household chores, allowed women to enter the labour market and virtually abolished professions like domestic service.”

Structural factors that are driving the demand for discretionary and convenience-seeking goods – such as increasing disposable income, urbanisation, rise in nuclear families, more women entering workforce and aspiration among customers – are key reasons for faster adoption of consumer appliances like the washing machines among households. Demand for washing machines and machine detergent powders and liquids (directly correlated) has grown steadily.

Although labour is quite cheap and available in surplus for low-skill jobs, most domestic workers in urban areas are not willing to wash clothes because it is time consuming and labour intensive job and usually the compensation is never enough. Demand for household appliances is not restricted only to metro cities, but also visible in rural areas. In 2017-18, washing machine penetration was 9% in rural areas vs. just 1% in 2012-13. In these areas, people purchase washing machines more as a status symbol rather than for convenience-seeking or problem-solving. Increasing rural electrification (almost 100% households have achieved electrification) and rapid strides in developing distribution network in rural and semi-urban areas has really helped washing machines to take off in a big manner.

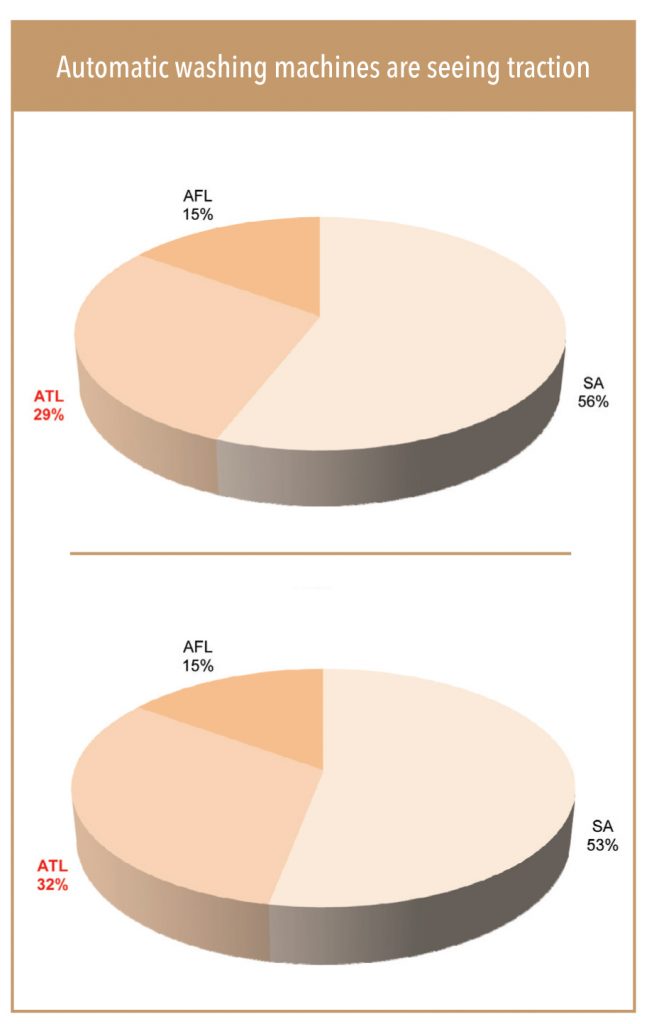

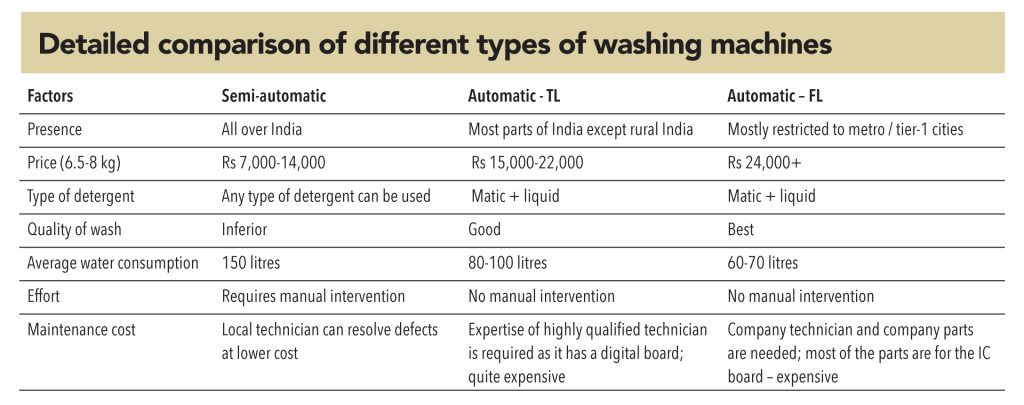

Shift towards automatic washing machines is inevitable

So far, semi-automatic machines have constituted 55-60% of the washing-machine market in volume terms due to higher price differential vs. automatic machines and the electricity problems in rural and semi-urban areas. However, semi-automatic machines take up too much time and effort, as customers have to keep a close watch on clothes during the entire cleaning process. The worst part is transferring wet clothes from one drum to another for spin-drying. As a result, automatic washing machines have seen a sharp uptick in past few years, with increasing time constraints, especially for urban households, and decreasing price difference between fully automatic and semi-automatic.

“With radical changes in lifestyles, the Indian consumer today seeks convenience in everything and is willing to pay a premium for the comforts that advanced technology brings in making everyday life much easier than ever. Hence the current owners of home appliances will always seek to upgrade to higher capacities and better technologies.”

– Kamal Nandi, Head and Executive Vice-president, Godrej Appliances.

Consumer durable companies and technicians strongly recommend using specific washing machines powders (i.e., matics) and liquid detergents while using automatic machines. With most of the new-age automatic washing machines having inbuilt steel plates, any other detergent (apart from matics and liquids) can cause significant corrosion to the steel plates and in turn reduce the life of the machine.

However, the change also comes from within. As Rupesh Patil, who has been in the business of repairing machines since the last five years said, “Consumer behaviour changes when they purchase an expensive item like an automatic washing machine and their tendency to purchase matics goes up. They want to keep their machine in good order.”

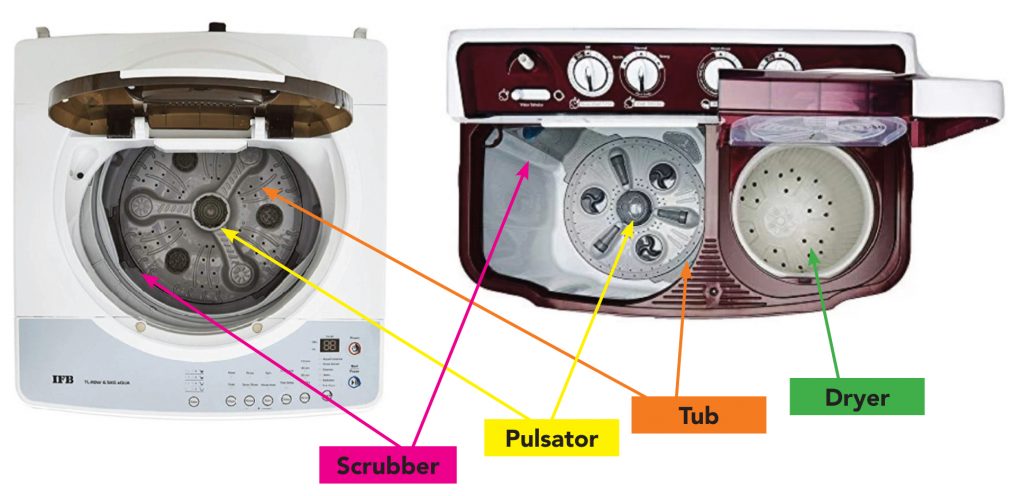

How do automatic top-load machines work?

• These machines contain a drum – the key part – placed on vertical axis on which a ‘pulsator’ has been affixed. This plays a key role in cleaning clothes. The other two components are the detergent chamber and scrubber. Water enters through pipes from the top, passes through the detergent chamber, and flushes the powder/ liquid onto the clothes, which are placed inside the machine.

• During the wash cycle, the pulsator turns around moving the clothes at the top and the bottom through water and they are brushed by the scrubber – removing stains and dirt. When the wash is finished, the pump at the bottom drains out the water and the cycle continues until the clothes are rinsed and spun dry.

• These machines have cleaning limitations. The pulsator tangle clothes leading to linting (threads coming out of garments); over a period, quality of clothes deteriorate.

• To avoid linting, Whirlpool India had come up with an in-built central agitator stick that was to prevent clothes from tangling. However, this did not work as planned. Many customers complained that the agitator was actually tearing their clothes.

How do front-load washing machines work?

• Front-load washers work by filling the bottom of the inner tub with a small amount of water and using the rotation of the tub and gravity to move the clothes through the water. The rotation action is similar to the tumbling action found in a clothes dryer. The side paddles on the inside drum lift the clothes and move them in and out of the water. This provides the mechanical action (scrubbing) needed to remove dirt/stains from fabric.

• Since these machines have an in-built water-heating mechanism, the process becomes better as hot water removes stains faster and from the root.

• This type of mechanical wash action (somewhat similar to traditional dhobi pachad method does not require clothes to be surrounded by water – thus using 40-50% less water than top-load machines at all times. This is why front-load washers use much less water than a standard top loader.

• Derived from traditional washing techniques, this machine completely eliminates linting.

Front-load washing powders need to have superior product formulation (to work with less water usage) that can remove dirt from the root cause with less foaming and without leaving any residue on clothes. Hence, front-load powders are about 10% more expensive than top-load detergents. While these machines provide the best wash quality, it comes at a price. They are about 10% more expensive than top-loads and require continuous supply of electricity and water, which may not be possible except in metros and tier-1 cities.

Technicians also claimed that if front-load machines break down, getting them up and running like before is a very expensive proposition. These machines also require more space than top-load washers and space, which has always been an issue in metro and tier-1 cities.

Matics are not failsafe

Even after taking all precautions and using the best matics, clogging (residue detergent accumulating at the bottom of the machine) can happen. This affects the machine’s performance. Liquid detergents (that fetch the highest margins for FMCG companies) can significantly enhance the performance of washing machines.

The great Indian jugaad. Yes, even while using machines!

Many households in rural and semi-urban areas do not feel any major urge to switch to automatic machines due to higher electricity costs. They also have ample time to manage manual household chores. Cleaning the semi-automatic washing machine regularly (quarterly) with some machine-cleaning powder (e.g., Scalegon brand) keeps their machines in reasonably good order. Indians have even found a way around the problem of continuous high-pressure water supply, even in automatic front-load machines) by installing pressure pumps (which cost additional Rs 3-4,000) on their home water-tank outlet pipe.

Deepika Bhandari, a resident of Udaipur, was proud of how she has maintained her machine with no problems at all! “I clean my semi-automatic machine using a mixture of hot water and washing machine cleaning powder on a quarterly basis and this has led to zero problems as this mixture removes all the residue from the bottom of the machine despite using it for more than five years,” she said.

Others have found their way around the white detergent staining problem while using automatic machines. Neeraj Ketke of Yawatmal district firmly believes that “all detergents are the same” and has no intention of using matics in his machine anytime soon. “I simply put the detergent powder at the bottom of machine instead of putting it in the detergent chamber and the problem of white stains goes away. I use a different method, almost opposite of what most detergent companies recommend while using matics, and I get the result that I want,” he grins proudly.

Indian machinenomics (jugaad) limits the growth prospects of premium detergents

Subscribe to enjoy uninterrupted access